What is blistering?

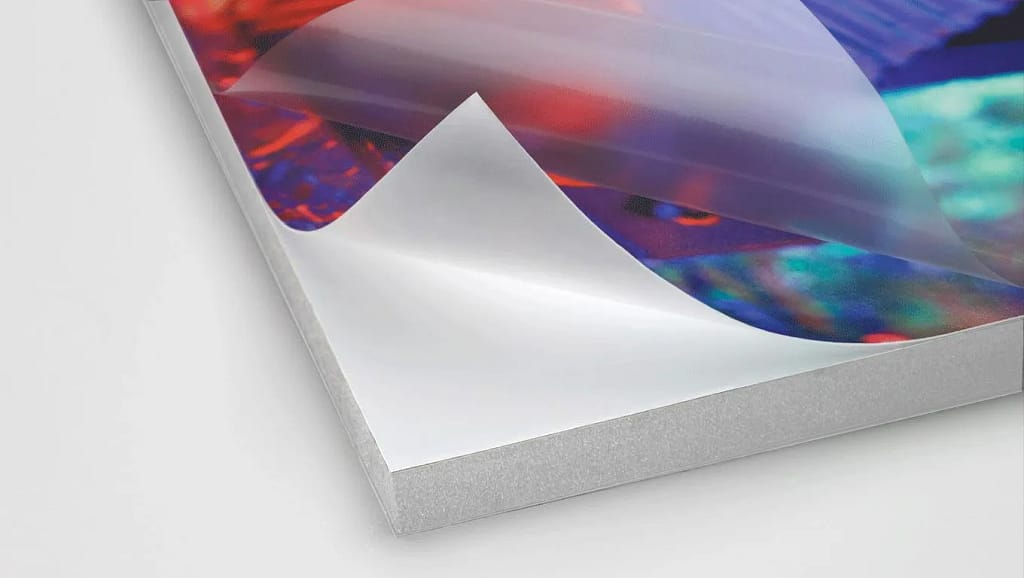

Blistering is when a picture is attached to a KT board and within a few days it starts to bubble up.

Why does foam board blister?

A. Short maturation period of the board core.

B. The PS film on the surface is too thin.

C.Paste a good picture blistering, the screen backing glue and PS surface have a reaction:.

1. there are some solvent-based glue backing, solvent in the backing

The glue application process in the oven did not evaporate thoroughly, there are residual solvents dissolved board cores lead to blistering;

2. water-based glue backing after the glue into the oven, due to too fast or oven temperature is not enough, resulting in water did not evaporate, there is residual moisture paste screen is not solid, the water is heated into water vapour, and the picture is too thin. Moisture into water vapour by heat to form pressure leading to blistering.

D. The process of formation

As the board core of the permaculture period far more than a week, a week is only relative, manufacturers store permaculture time is not enough, or the surface of HIPS surface is too thin, due to workers operating the processing process (too high temperature burn sheet, too low temperature is not fully foamed, production speed too fast, grinding roller spacing is too large), resulting in the core or surface skin heating and lamination is not firm, resulting in blistering, at this time in the foaming gas inside the sheet overflows to form a bubble, which is the factor that causes the traditional ordinary KT board to blister itself.

E.PS sheet foaming into pearl board, due to PS plastic contains other plastic impurities, there is no foaming craters lead to blistering.

At present, there are many different types of foam board surface materials, with the main new products being paper, paper laminated film, PVC film, HIPS film, HIPS + PVC composite film, HIPS+PP composite film, pre-coated paper surface, glue surface, and even cloth surface. ANBO company guarantees that foam boards laminated with PVC film, HIPS+PVC laminate, HIPS+PP laminate, paper and paper laminate are completely blister-free and can be used with confidence.

While blistering isn’t a common problem for foam board manufacturers, it is a major issue for retailers and manufacturers of sandwich products. To avoid blistering, you should use the right type of foam board for your products. ANBO company offers more than twenty types of foam board for you to choose from, please let us know your application and requirements and we will assist you in finding the best product for you.