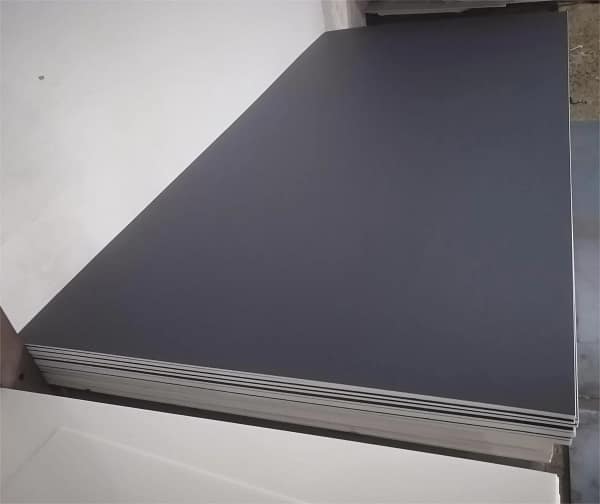

The products are widely used in digital imaging, photographic,graphic arts industries, packaging, decoration, engraving, kitchen cabinet, construction, modeling areas and food packaging industry etc.

With 12 years of development, ANBO has grown to an annual production capacity of 40,000 tons of foam board and 18 million sheets of PS foam board. 12 years of focus on making boards, our products are sold in more than 100 countries and regions, mainly exporting to Southeast Asia, USA, South America, Oceania, Middle East and Europe. Our customers have a high opinion of us, which is due to our professional service, high quality products and reasonable prices. ANBO positions itself as a top material solution provider with unlimited possibilities of advertising and decorative materials, home building materials and superb service.

In the future, ANBO company will continue to focus on making good boards and supplying more good products to our customers.We wish more customers to create more value with us and achieve a win-win situation together.

Services we can offer

Our exclusive manufactured Advertising and decoration solutions are complimented by our comprehensive range of services developed to make us your one stop shop for all your Advertising,Home decoration and Food packaging project needs.

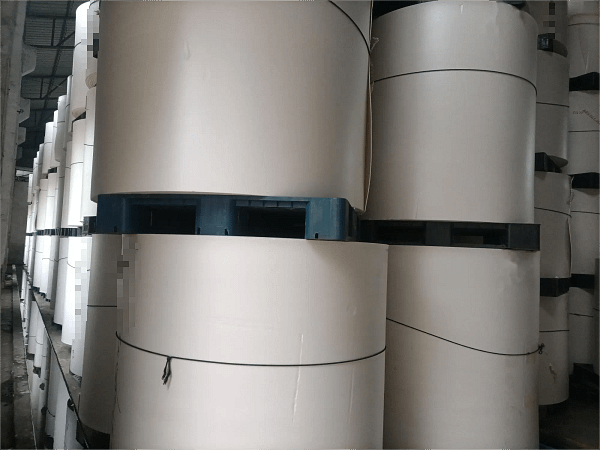

Packing and Feedback

Packed on fumigation-free pallets or in new, thickened cardboard boxes to effectively protect the product from damage during transport. Feedback tracking logistics information at any time to ensure that the goods reach you safely.

Customized production

We have strong R&D capabilities to meet your customisation needs. Please let us know your requirements or samples and a customised solution will be proposed for you

Free samples

We can provide free samples if needed. However, you will be required to pay for express, which can be refunded on subsequent orders.

Production follow-up

During the production process our quality control staff will check the quality of the product, including the thickness, size and density of the boards to ensure it meets the standard quality requirements. If it is not within the acceptable range, it will be classified as a failing product and will be pulled out and scrapped. The customer is guaranteed to receive an A-grade product. In addition, production progress, pictures and videos can be shown to the customer so that he is always aware of the production progress of his order.