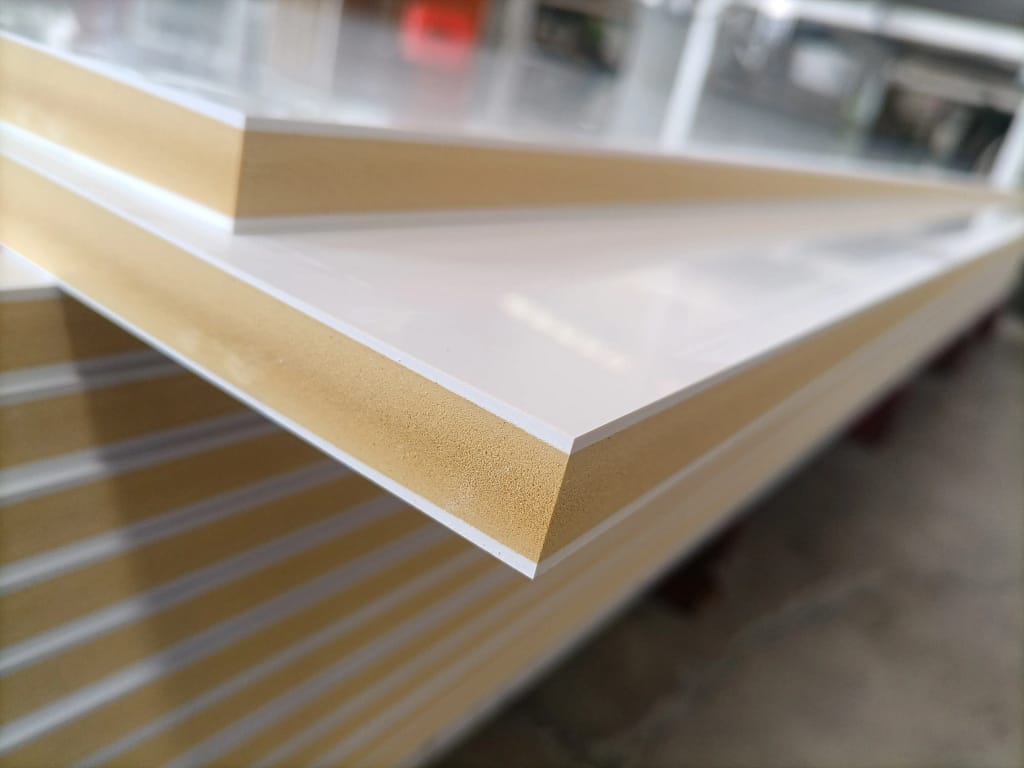

WPC Co-extruded foam board is a type of foam board made from 3 layers. It is also known as WPC, or wood plastic composite. This type of material has become more and more popular in recent years, especially among builders who are looking for cost-effective materials that can be processed easily and quickly. The biggest advantage of using WPC over other types of construction materials is its affordability compared to other options. Another great thing about this material is the fact that it doesn’t require any additional treatment after it has been installed. You just need to seal the seams with hot glue and you are good to go. WPC Co-extruded foam board is made from two different types of materials: wood powder and plastic resin. In this article, we will explore how WPC Co-extruded foam board differs from another similar product –WPC celuka foam board – so that you have an understanding of what these two terms mean if you come across them while shopping for a construction material.

What is WPC Celuka Foam Board?

WPC is a composite material that is made from PVC powder and straw powder. The plastic resin creates a strong plastic board that is odor resistant, moisture resistant, and can be painted or stained to match any room decoration. The straw powders are sourced from sustainable sources and are ground to create a fine powder. The powder is then combined with polyvinyl acetate to create the board’s raw material. The polyvinyl acetate then acts as a binder to hold the wood particles together. The polyvinyl acetate also gives the boards their characteristic smell and taste, which is why WPC is often referred to as “wood-wood.”

Differences Between WPC Co-extruded foam board & WPC Celuka Foam Board

There are many differences between WPC-Co-extruded foam board and WPC celuka foam board that make this type of material a great choice for construction projects. For starters, WPC celuka foam board is made from straw powder, and this makes it a more eco-friendly choice compared to WPC-Co-extruded foam board. WPC celuka foam board is also less expensive than WPC-Co-extruded foam board. Most importantly, WPC celuka foam board has better weather resistance than WPC-Co-extruded foam board. This means that it is better suited for outdoor use. The two materials may look almost the same, but they have some significant differences.

Advantages of WPC Co-extruded foam board

- Affordability - On average, WPC-Co-extruded foam board costs is much less than other types of construction materials. -

Eco-Friendly - Compared to other types of construction materials, WPC-Co-extruded foam board is recyclable, so the boards are a great choice for the environment. -

Durability - WPC-Co-extruded foam board is durable and resistant to moisture, so it will last long even when exposed to the elements. -

Fire Retardant - WPC-Co-extruded foam board is fire retardant, which means that it will not burn and create toxic fumes during a fire. -

Low Maintenance - WPC-Co-extruded foam board has very low maintenance needs. Since there are no added coatings or treatments, you don’t have to worry about keeping this type of material clean and looking good.

Conclusion

In general, the WPC Co-extruded foam board is a 3 layers structure, similar to a sandwich, while the WPC celuka foam board is a single-layer structure. In terms of raw materials, the WPC Co-extruded foam board is made of wood flour and resin powder, while the WPC celuka foam board is made of straw powder and resin powder. In terms of application, both types of board can be used in the furniture industry, such as wardrobes, cabinets etc. In terms of characteristics, both types of boards are water and moisture resistant, termite resistant, environmentally friendly and formaldehyde free, flame retardant, etc. To choose which one, please contact ANBO company and we will recommend the right product for you according to your application.